Our client is a global, independent energy company who was looking for a way to collect data from the electrical equipment on their Deepwater assets — such as motors, drives, and power distribution — without having to send personnel to perform dangerous periodic checks manually.

It was difficult and labor-intensive to predict failure points and identify other maintenance necessities.

Expensive annual inspections became less reliable, as potential failures cannot be timed with the inspection schedule.

The team was often left in a position in which they could only investigate failures after they had already occurred.

The Enginuity Global team tasked multiple business units with collaborating on the development and implementation of a system that would provide real-time information access while improving personnel safety.

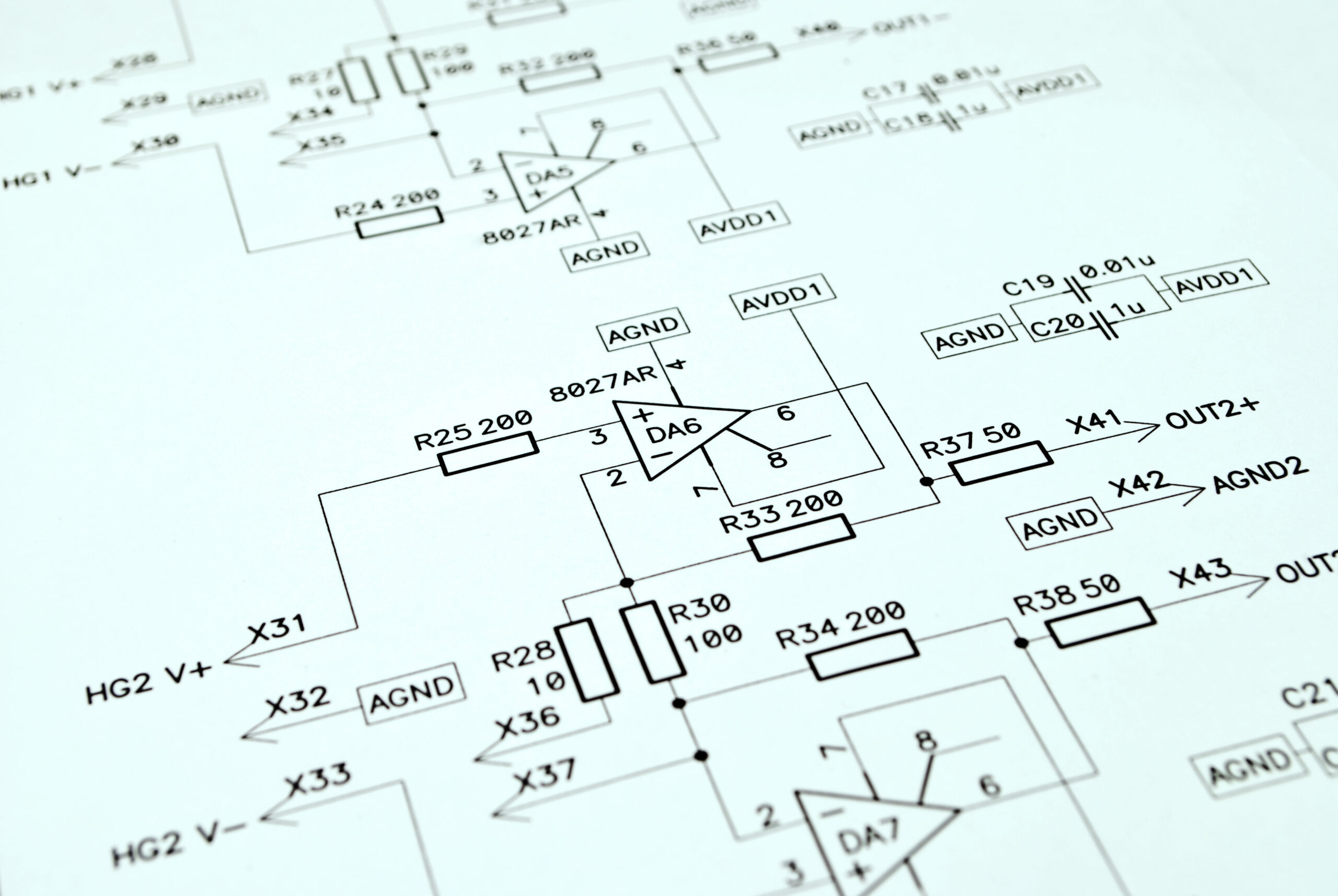

Our Electrical Engineering team developed and provided detailed drawings for 3 different approaches to system design that could capture the required data for the client.

This data included temperature, variance in amperage and voltage, local alarms, and the ability to monitor medium- and low-voltage systems on both input and output (line and load) sides of their systems.

The client chose to install all 3 systems, running them in parallel to discover which best suited their needs.

Our Field Services team installed them in separate locations and our Automation + Controls team tied them into the client’s monitoring (DCS) system so that the tests could start generating results.

Our client’s new system provides immediate alerts to potential problems to assist in maintaining and preventing power outages and failures with no need for human interaction.

Our work was implemented so well that one of the manufacturers of the systems we installed approached us to become a preferred installer, adding more in-depth resources, training, knowledge, and support as well as visibility.

Enginuity still helps monitor these systems today, and we have documented all lessons learned as well as pros and cons of the different systems.

Partnering with Stratus on a digital transformation

Mitigating operational and personnel safety issues

Filling the gaps at remote job sites

Get the latest updates and learn more about all of our most recent accomplishments.

Ⓒ 2024 Enginuity Global